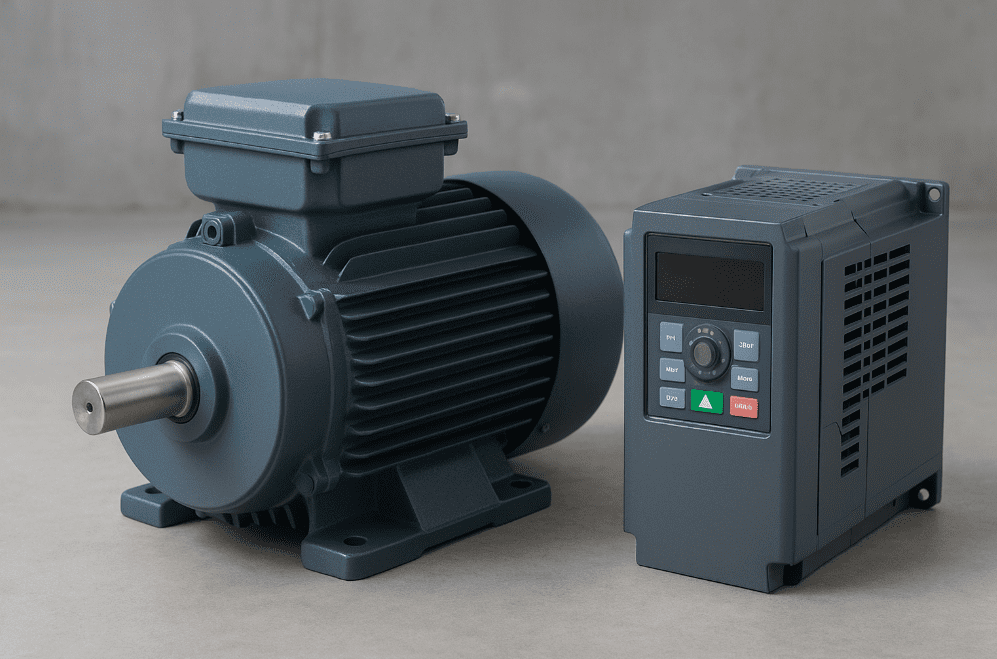

Variable-frequency drives (VFDs) have changed the way industries use electric motors. Instead of running at a fixed speed, a VFD allows motors to operate at variable speeds, saving energy, improving performance, and increasing control. But not every electric motor can handle the stresses of VFD operation. This is where inverter rated motors, also known as inverter duty motors, become essential.

A standard motor may run on a VFD for a short time, but its insulation, bearings, and cooling systems are not designed for the electrical and thermal challenges created by high-frequency switching. Over time, this leads to overheating, insulation breakdown, and reduced lifespan. In contrast, inverter rated motors are specially engineered to handle these conditions. They deliver consistent performance, operate efficiently across a wide speed range, and last much longer than conventional motors when paired with a VFD.

This article explains what makes a motor inverter rated, why choosing one is important, and how Innotec Power provides advanced inverter rated motor solutions for different industries.

| wdt_ID | wdt_created_by | wdt_created_at | wdt_last_edited_by | wdt_last_edited_at | Model No. | Continuous Rating Power (kW) | Continuous Rating Torque (Nm) | Power (kW) at 60 Minutes | Torque (Nm) at 60 Minutes | Power (kW) at 15 Minutes | Torque (Nm) at 15 Minutes | Rated Speed (RPM) | Cooling |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:47 AM | 255-AZZS565-002 | 1.0 | 91.4 | 1.1 | 113.5 | 1.4 | 176.2 | 100 | Natural |

| 2 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:47 AM | 255-AZZS565-006 | 3.7 | 46.7 | 4.7 | 58.2 | 7.5 | 92.5 | 750 | Natural |

| 3 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:47 AM | 255-AZZS565-012 | 7.5 | 46.7 | 10.2 | 57.6 | 14.8 | 92.5 | 1,500 | Natural |

| 4 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:48 AM | 255-AZZS565-014 | 8.5 | 47.6 | 11.8 | 59.3 | 18.7 | 94.2 | 1,800 | Natural |

| 5 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:48 AM | 255-AZZS565-016 | 10.0 | 46.6 | 12.8 | 58.2 | 20.0 | 92.3 | 2,000 | Natural |

| 6 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:48 AM | 255-AZZS565-024 | 15.0 | 46.7 | 20.6 | 58.1 | 32.8 | 92.5 | 3,000 | Natural |

| 7 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:51 AM | 360-AEZS400-065 | 27.0 | 317.6 | 33.5 | 395.7 | 52.6 | 621.0 | 800 | Natural |

| 8 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:51 AM | 360-AEZS565-065 | 35.0 | 317.4 | 53.7 | 395.5 | 76.0 | 621.0 | 1,000 | Natural |

| 9 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:52 AM | 360-AZZS400-040 | 17.3 | 217.0 | 27.0 | 270.3 | 40.0 | 424.0 | 760 | Natural |

| 10 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:52 AM | 360-AZZS400-050 | 20.0 | 81.4 | 28.2 | 270.3 | 44.3 | 424.0 | 900 | Natural |

| 11 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:52 AM | 360-AZZS565-014 | 8.8 | 213.0 | 11.0 | 265.0 | 17.2 | 416.0 | 400 | Natural |

| 12 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:53 AM | 360-AZZS565-040 | 20.0 | 217.0 | 30.5 | 270.0 | 48.0 | 424.0 | 900 | Natural |

| 13 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:53 AM | 360-AZZS565-050 | 28.0 | 217.0 | 39.5 | 270.3 | 55.8 | 424.0 | 1,200 | Natural |

| 14 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:54 AM | 360-BEZS565-030 | 18.0 | 570.0 | 23.3 | 708.8 | 27.8 | 1,109.2 | 300 | Natural |

| 15 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:54 AM | 360-CCC565S-022 | 13.5 | 716.7 | 16.8 | 891.6 | 26.3 | 1,398.6 | 180 | Natural |

| 16 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:50 AM | 360-CZZS565-020 | 12.3 | 651.9 | 15.3 | 811.0 | 24.0 | 1,272.0 | 180 | Natural |

| 17 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:50 AM | 360-CZZS565-022 | 14.0 | 645.5 | 17.4 | 803.3 | 24.2 | 1,260.0 | 200 | Natural |

| 18 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:50 AM | 360-CZZS565-024 | 14.7 | 626.4 | 18.3 | 779.6 | 28.8 | 1,224.2 | 220 | Natural |

| 19 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:55 AM | 360-DZZS565-030 | 18.0 | 912.0 | 23.5 | 1,134.0 | 32.7 | 1,774.8 | 190 | Natural |

| 20 | Harshit | 16/04/2025 11:40 AM | Harshit | 16/04/2025 11:55 AM | 360-GZS565-002 | 1.0 | 152.0 | 1.2 | 189.2 | 1.6 | 297.0 | 60 | Natural |

| 21 | Harshit | 15/07/2025 09:36 AM | Harshit | 15/07/2025 09:36 AM | 360-GZS565-012 | 7.0 | 146.0 | 9.4 | 181.9 | 14.8 | 285.6 | 450 | Natural |

| 22 | Harshit | 15/07/2025 09:37 AM | Harshit | 15/07/2025 09:37 AM | 360-GZS565-014 | 8.5 | 149.0 | 11.0 | 185.6 | 17.2 | 291.2 | 550 | Natural |

| 23 | Harshit | 15/07/2025 09:38 AM | Harshit | 15/07/2025 09:38 AM | 360-GZS565-020 | 11.0 | 152.0 | 15.6 | 189.2 | 24.6 | 296.6 | 700 | Natural |

| 24 | Harshit | 15/07/2025 09:40 AM | Harshit | 15/07/2025 09:40 AM | 255-HZS565-012 | 7.5 | 38.2 | 9.4 | 47.7 | 14.9 | 75.6 | 1,800 | Natural |

| 25 | Harshit | 15/07/2025 09:41 AM | Harshit | 15/07/2025 09:41 AM | 255-HZS565-014 | 7.8 | 38.0 | 10.9 | 47.5 | 17.3 | 75.3 | 1,900 | Natural |

| 26 | Harshit | 15/07/2025 09:42 AM | Harshit | 15/07/2025 09:42 AM | 255-HZS565-020 | 11.0 | 38.7 | 14.5 | 48.4 | 23.1 | 76.8 | 2,800 | Natural |

| 27 | Harshit | 15/07/2025 09:43 AM | Harshit | 15/07/2025 09:43 AM | 255-DZS565-006 | 3.5 | 19.1 | 4.7 | 23.8 | 7.5 | 37.8 | 1,800 | Natural |

| 28 | Harshit | 17/07/2025 12:21 PM | Harshit | 17/07/2025 12:21 PM | 360-CCCS565-014 | 7.5 | 709.5 | 10.8 | 882.9 | 15.0 | 1,385.4 | 100 | Natural |

| 29 | Harshit | 17/07/2025 12:23 PM | Harshit | 17/07/2025 12:23 PM | 360-CCCS565-200 | 120.0 | 722.4 | 169.4 | 900.2 | 262.8 | 1,411.7 | 1,600 | Natural |

| 30 | Harshit | 17/07/2025 12:24 PM | Harshit | 17/07/2025 12:24 PM | 360-CEZS565-028 | 17.0 | 745.6 | 21.8 | 927.9 | 34.3 | 1,456.1 | 220 | Natural |

| 31 | Harshit | 17/07/2025 12:25 PM | Harshit | 17/07/2025 12:25 PM | 360-CEZS565-200` | 120.0 | 760.6 | 168.2 | 946.2 | 263.8 | 1,483.7 | 1,500 | Natural |

| Model No. | Continuous Rating Power (kW) | Continuous Rating Torque (Nm) | Power (kW) at 60 Minutes | Torque (Nm) at 60 Minutes | Power (kW) at 15 Minutes | Torque (Nm) at 15 Minutes | Rated Speed (RPM) |

What Makes a Motor Inverter Rated?

A motor earns the “inverter rated” designation through several design improvements that prepare it for the demanding environment of variable-frequency operation.

Enhanced Insulation Systems

Voltage spikes and fast switching pulses are common in VFD systems. These stresses can quickly damage the insulation of a standard motor. Inverter rated motors solve this problem by using higher-grade insulation materials, reinforced winding designs, and form-wound coils. These upgrades prevent premature insulation failure and ensure long-term reliability.

Improved Thermal Management

Cooling becomes a major challenge at low speeds, when a motor’s built-in fan moves less air. Without additional protection, this heat buildup can damage the motor. Inverter duty motors include special insulation capable of withstanding higher temperatures, extra cooling fins, or even external blowers to maintain safe operation. Some advanced designs also support liquid cooling for heavy-duty applications.

Bearing Protection

The high switching frequencies of a VFD can create shaft currents that erode bearings. Over time, this leads to pitting, noise, and bearing failure. To avoid this, inverter rated motors are equipped with insulated bearings or grounding rings that safely discharge harmful currents. This design feature significantly increases motor life.

Wide Speed Range

Standard motors usually perform well only within a narrow constant-torque range. In contrast, inverter rated motors are engineered to provide torque across a wide range of speeds, including zero-RPM torque at startup and higher-than-base speed operation when required. This makes them more versatile for industrial and mobile applications.

Robust Mechanical Design

Frequent acceleration, deceleration, and direction changes are common in VFD systems. To withstand these demands, inverter rated motors use stronger frames, rotors, and shafts. This durability ensures long service life even in tough working conditions.

Why Choosing the Right Motor Matters

Using a standard motor in a VFD system may seem cost-effective at first, but the long-term risks outweigh the initial savings. Standard motors are more likely to overheat, fail under stress, and cause unplanned downtime. This results in expensive repairs and interruptions in production.

On the other hand, inverter rated motors are designed to work seamlessly with VFDs. They maintain precise speed control, operate efficiently at different loads, and offer extended service life. The improved reliability reduces maintenance needs and ensures smooth operation. In addition, they help achieve energy savings by enabling more accurate speed adjustments in pumps, fans, conveyors, and other systems.

For businesses that depend on continuous, reliable operation, choosing inverter rated motors is not just a smart choice—it is essential for efficiency, performance, and long-term cost savings.

Innotec Power’s Inverter Rated Motor Solutions

At Innotec Power, we design inverter rated motors with a focus on durability, efficiency, and customization. Each solution is engineered to match the requirements of modern industries, ensuring optimal compatibility with VFD systems.

Our motors feature:

High-efficiency platforms – Available in permanent magnet synchronous or induction motor designs, providing higher torque density and improved efficiency.

Premium insulation and cooling – Using Class F or H insulation systems and optional liquid-cooled housings for demanding environments.

Customizable feedback systems – Options include Hall sensors, encoders, or sensorless designs to suit different control needs.

Bearing and shaft protection – Built-in insulation or grounding features safeguard against bearing damage.

Flexible voltage options – Standard motors range from 24 V to 350 V, with custom solutions available for unique drive requirements.

To simplify integration, Innotec Power can also supply a pre-programmed VFD controller along with the motor. This turnkey package ensures that the motor and drive are perfectly matched, delivering maximum efficiency and performance. Whether you need a compact auxiliary motor or a large drive system, our engineering team tailors each solution to your specific application.

Applications and Industries

Inverter rated motors are versatile and suitable for a wide range of industries. Common applications include:

Conveyors and material handling – Providing smooth, reliable speed control for continuous operation.

Pumps and fans – Enabling precise flow control and reducing energy consumption.

Mixers, extruders, and machine tools – Offering accurate torque and speed control for production processes.

E-mobility and industrial vehicles – Delivering durability, wide speed range, and efficient cooling for electric drive systems.

HVAC and fluid handling systems – Maintaining energy efficiency across variable seasonal loads.

These examples highlight the adaptability of inverter rated motors, making them a preferred choice across both industrial and mobile power applications.

Partner With Innotec for Inverter Rated Motors

Selecting the right motor for a VFD application is critical. A generic motor may not survive the electrical and mechanical stresses of variable-speed operation, leading to costly failures. Innotec Power’s inverter rated motors are engineered to provide long-lasting performance, precise speed control, and energy efficiency.

With flexible design options, advanced insulation systems, and robust construction, our motors are trusted in industries ranging from manufacturing to transportation. Whether your project requires a small motor for an auxiliary system or a large motor for a demanding industrial process, our team can design and deliver the right solution.

Contact Innotec Power today to discuss your requirements. Our engineers will work with you to select or customize the perfect inverter rated motor and drive package for your application.